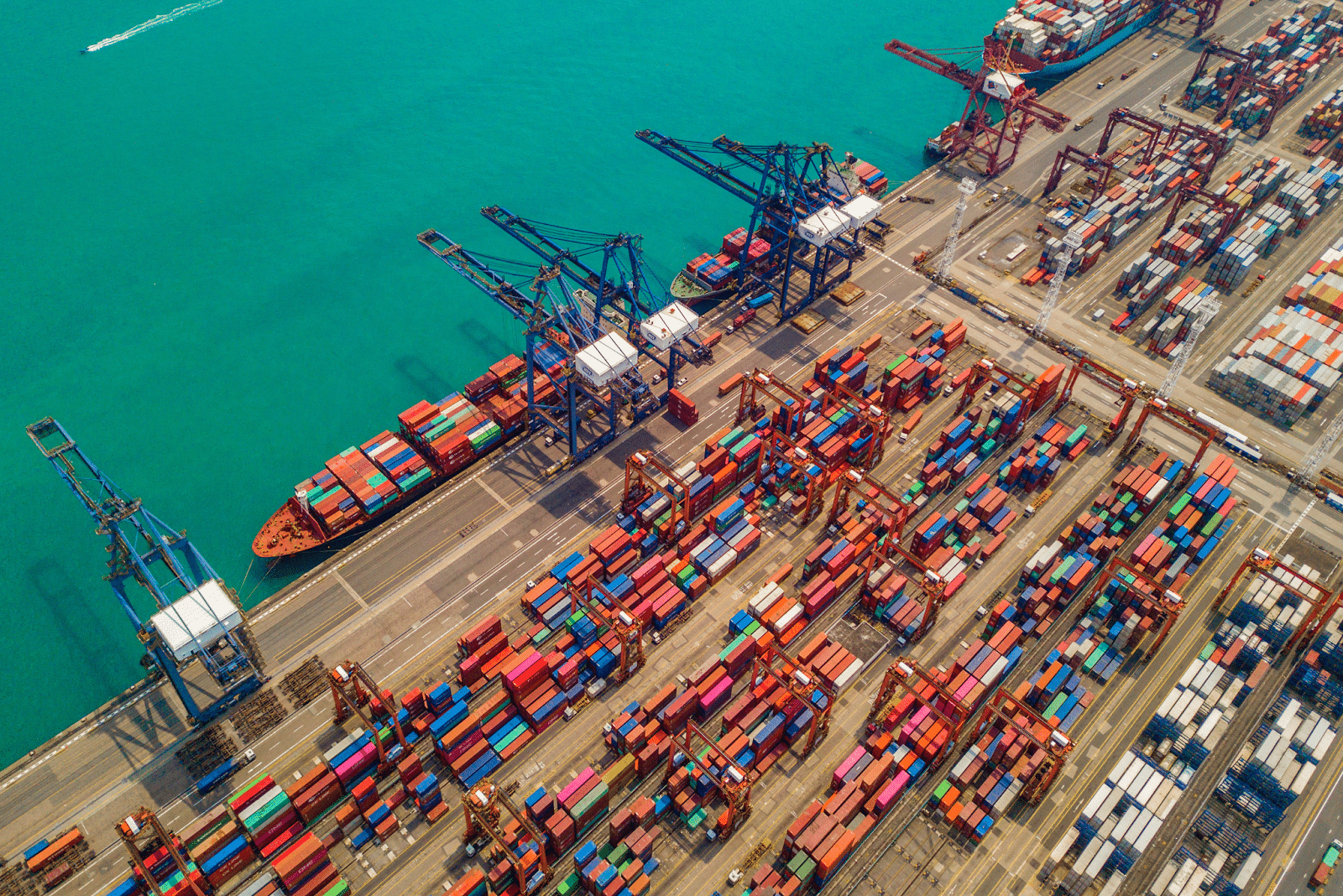

Let’s skip the formalities. This is about ensuring you build a supplier network resilience that’s ready for anything the world throws at it. You’ve seen how quickly things can go wrong: ports close, transport gets delayed, suppliers go offline. The goal is simple: build supplier network that continually strengthens itself, no matter what.

Why It Matters to Build a Strong Supplier Network

Global supply chains are more fragile than ever. A single missing shipment can stall production for weeks. Building a network that can absorb shocks means you keep delivering, even when others can’t. That’s what true supply chain resilience looks like.

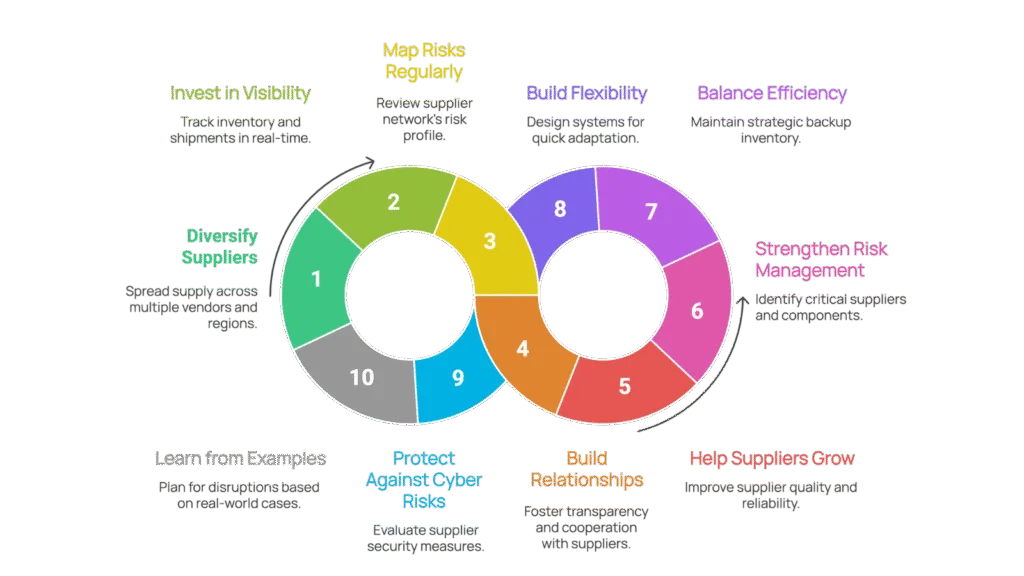

1. Diversify Your Supply Base

Relying on one or two suppliers might save time now, but it’s a risk you can’t afford long-term. Spread your supply across multiple regions and vendors.

Example:

- Supplier A in one country offers speed.

- Supplier B in another offers stability.

- Supplier C might cost more, but ensures quality.

This way, you have options if one gets disrupted.

2. Invest in Real-Time Visibility

If you can’t see what’s happening in your supply chain right now, you’re already behind. Real-time tracking of inventory and shipments lets you respond before a small issue becomes a crisis. Dashboards, GPS tracking, and instant reporting can make all the difference.

3. Map Risks Regularly

Set aside time to review your supplier network’s risk profile. Look at factors like political instability, financial health, and even weather patterns.

A quarterly review works well, but also check after major world events. That way, you’re not caught off guard by sudden changes.

4. Build Supplier Network and relationships

A supplier is more than just a transaction. When you invest in a relationship, you get transparency and cooperation in return.

Regular check-ins, performance reviews, and honest communication create a partnership where suppliers want to prioritize you, even in tough times.

5. Help Your Suppliers Grow

Your supply chain is only as strong as the weakest link. If a supplier struggles with quality or reliability, work with them to improve.

Supplier development programs can lead to fewer defects, faster production, and better outcomes for both sides.

6. Strengthen Risk Management

A good risk management plan identifies your most critical suppliers and components. It also includes a response strategy, what to do when something goes wrong.

Think about alternate suppliers, backup shipping routes, and extra capacity for essential products.

7. Balance Efficiency with Redundancy

While lean operations save money, they can also leave you exposed. Having strategic backup inventory or secondary suppliers may seem costly, but it’s far cheaper than a shutdown.

8. Build in Flexibility

If your network can’t pivot quickly, disruptions hit harder. Design your system so you can switch to alternate suppliers, routes, or production methods without losing time.

9. Protect Against Cyber Risks

Cyberattacks can shut down a supplier just as effectively as a storm. Evaluate your suppliers’ security measures, share best practices, and ensure there’s a plan in place if a breach happens.

10. Learn from Real-World Examples

Companies that survived major disruptions often had one thing in common: preparation. They didn’t just hope for the best; they planned for the worst. That’s the mindset you need to cultivate.

Bringing It Together

A resilient supplier network isn’t built overnight. To build supplier network strength, it takes deliberate planning, smart relationships, and ongoing risk management.

Here’s your action list:

- Diversify suppliers

- Monitor in real time

- Review risks regularly

- Build trust

- Support supplier growth

- Have a solid risk plan

- Maintain backups

- Stay flexible

- Secure against cyber threats

- Keep learning

Ready to Build a Supplier Network Strength with Importivity?

Global disruptions don’t wait for you to catch up, so why wait to build a supplier network that’s ready for anything? At Importivity, we help businesses like yours create strong, flexible, and resilient supply chains that keep moving no matter what happens in the world.

Let’s talk about your goals and map out a plan that works for your business today and stands strong tomorrow.

Frequently asked questions

How often should I review my supplier risks?

Quarterly, plus whenever major events occur that could impact your network.

Should I always keep backup suppliers?

Yes. Even if you rarely use them, they’re insurance against disruptions.

Can smaller businesses build supply chain resilience?

Start small and grow your strategies over time.

What’s the quickest way to improve visibility?

Adopt simple tracking tools that let you see real-time inventory and shipment status.

What’s the first step if I have no resilience plan?

Start by mapping your top suppliers and identifying their biggest risks.