Ever wonder why some competitors seem to predict problems before they happen and adapt faster than you thought possible? Often, the difference isn’t luck. It’s supply chain digitization. They’re not just adding software for the sake of it; they’re using it to create a genuine competitive advantage. This isn’t about jargon or hype, it’s about what works in the real world.

Visibility is the quiet Superpower

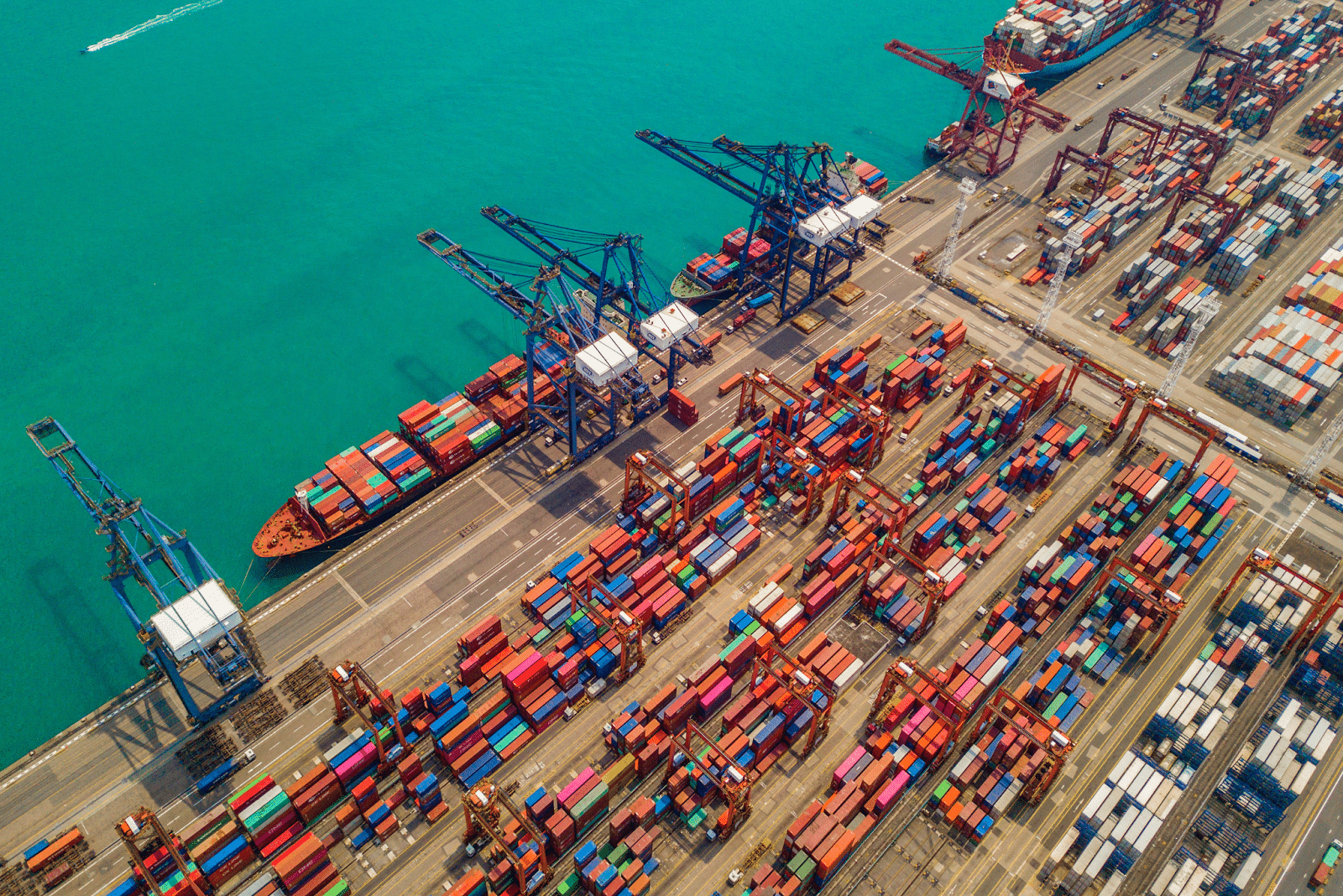

Competitors who excel at supply chain digitization know that true visibility changes everything. Being able to track products, shipments, and inventory in real time means you can spot trouble before it becomes costly. That’s fewer stockouts, smarter routing, and smoother customer experiences.

The edge comes from acting on this visibility. Instead of reacting after the fact, they plan, adjusting production, rerouting shipments, or shifting resources to prevent bottlenecks before they even form.

Resilience beats efficiency alone

Many companies chase efficiency, but the smart ones build resilience alongside it. Supply chain digitization allows automation, connected systems, and predictive analytics to work together, giving them the ability to respond quickly when disruptions hit. Whether it’s a delayed shipment, a supplier issue, or a market shift, these companies adapt while others scramble.

Over time, this resilience pays off. Businesses that can keep moving when others stall naturally win more market share and keep customers loyal.

Competitive Advantage Through Supply Chain Digitization

What separates a business that survives from one that thrives often comes down to foresight. Supply chain digitization provides that foresight by connecting the dots between suppliers, logistics partners, and customer demand. When businesses have a real-time view of these moving parts, they can predict issues before they become problems.

For example, a company might see early signs of a shipment delay in its system. Instead of waiting until a customer complains, they can reroute deliveries or adjust production schedules to minimize disruption. That type of proactive action is what creates a real competitive advantage. It is not about having the most advanced technology for the sake of it, but about using the right tools to make better, faster decisions.

Over time, this builds customer confidence. People naturally choose brands that deliver reliably, even when market conditions are unpredictable.

1. Small players are finding big wins using Supply Chain Digitization

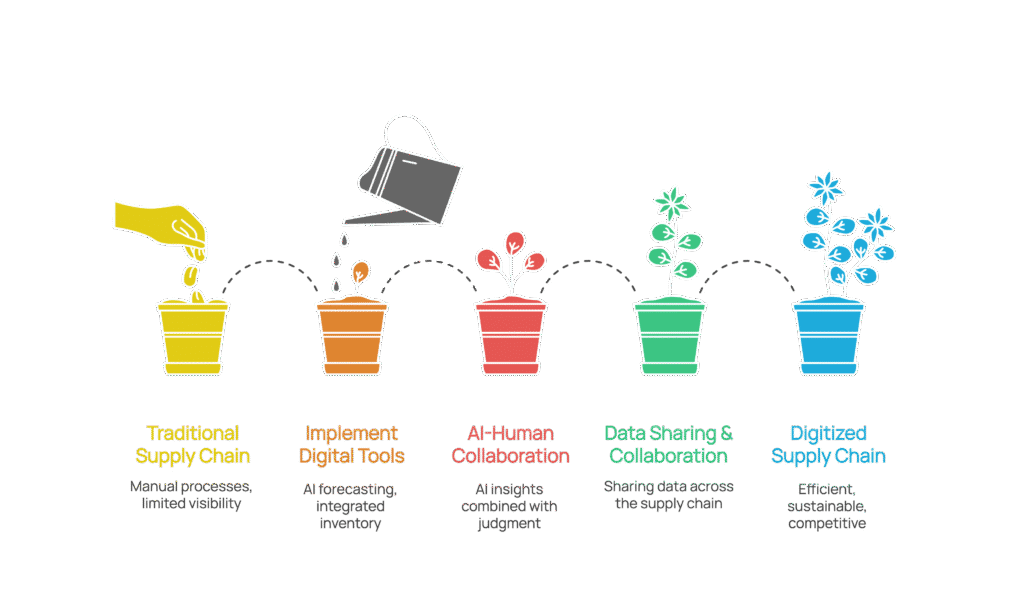

It’s not just the giants benefiting. Smaller and mid-sized companies are using supply chain digitization tools like AI-powered forecasting and integrated inventory systems to compete with much larger rivals. They can now manage stock with precision, forecast demand more accurately, and control costs, all without the need for massive budgets.

For these businesses, digitization levels the playing field. They can serve customers faster, react to change with agility, and maintain profitability in competitive markets.

2. AI supports better decisions, not replaces them

The best players don’t treat AI as a silver bullet. They see it as a decision-support partner. Within supply chain digitization, AI processes huge amounts of operational data, spotting patterns and predicting potential issues. But humans still make the final call.

From forecasting demand and identifying supplier risks to optimizing delivery routes, AI is making decisions faster and more precisely. The advantage comes from combining AI insights with experienced judgment.

3. Collaboration multiplies results

The companies ahead in supply chain digitization know that working in isolation limits progress. They share data with suppliers, carriers, and even customers so that everyone is operating from the same up-to-date information.

This collaboration reduces delays, improves planning accuracy, and builds stronger relationships across the chain. Everyone benefits from fewer surprises and smoother operations.

4. Sustainability gets a real boost

Competitors are also using supply chain digitization to improve sustainability. Accurate, connected data makes it easier to trace materials, cut waste, and run greener operations. Whether it’s choosing the most efficient transport routes or ensuring suppliers meet environmental standards, digitization supports these efforts.

Customers are increasingly drawn to brands that can prove they’re reducing their footprint, making sustainability another layer of competitive advantage.

5. Starting small is smarter than chasing hype

Some businesses rush into the latest tech trends without a clear strategy. The ones doing it right start small, focusing first on areas where visibility is weakest. That might mean digitizing inventory management, connecting order systems, or automating shipping updates.

Supply chain digitization works best when it builds on a solid foundation. Once those foundations are in place, businesses expand carefully, ensuring each step genuinely improves performance rather than just adding complexity.

How Importivity Can Help You digitize your supply chain

At Importivity, we’ve helped companies move from manual, disconnected processes to fully digitized supply chains where clarity replaces chaos. One client went from chasing shipment updates for days to knowing exactly when their delivery would arrive, down to the hour. That kind of control doesn’t just reduce stress, it builds trust.

If you’re ready to see how supply chain digitization can give you a competitive advantage, visit our Supply Chain Management Services page to explore how we can support your next step.

Frequently Asked Questions

What is supply chain digitization?

It’s the shift from manual, disconnected processes to connected digital systems like real-time tracking, analytics, and automation.

How does supply chain digitization give a competitive advantage?

It allows faster, more informed decisions, reduces waste, improves resilience, and helps companies adapt to change ahead of competitors.

Can small businesses benefit from supply chain digitization?

Yes. Affordable cloud and AI tools mean even smaller companies can improve visibility and performance without huge investments.

Is AI essential for supply chain digitization?

AI isn’t required, but it adds value by processing data quickly and spotting patterns, supporting better decisions without replacing human expertise.

Where should a business start with supply chain digitization?

Begin by identifying the biggest gaps in visibility or efficiency, digitize those first, and expand once the foundations are strong.